Maintaining compliance in a busy New England commercial facility is rarely straightforward. Property managers face ongoing pressure to balance evolving health regulations with the daily demands of multiple tenants. Efficient industrial cleaning is more than routine upkeep, it is the foundation for safety, tenant satisfaction, and regulatory peace of mind. By understanding the core concepts of industrial cleaning, property managers can confidently choose solutions that uphold workplace standards and foster trust across every occupied space.

Table of Contents

Key Takeaways

| Point | Details |

|---|---|

| Importance of Compliance | Industrial cleaning must adhere to stringent regulatory standards to ensure safety and operational efficiency across various sectors. |

| Advanced Cleaning Technologies | Modern cleaning methods incorporate technologies like ultrasonic cleaning and UV-C sterilization, enhancing the effectiveness of contaminant removal. |

| Risk Management Strategies | Organizations should implement robust risk assessment frameworks and validation processes to mitigate financial and legal liabilities associated with cleaning lapses. |

| Documentation and Validation | Detailed documentation of cleaning protocols and validation processes is essential when selecting industrial cleaning services to ensure compliance with industry standards. |

Defining Industrial Cleaning and Core Concepts

Industrial cleaning represents a systematic and specialized approach to sanitizing and maintaining complex environments where standard cleaning methods prove inadequate. Unlike residential or commercial cleaning, industrial cleaning involves rigorous processes designed to meet strict regulatory standards and ensure operational efficiency across manufacturing, pharmaceutical, food processing, and technical facilities.

At its core, industrial cleaning encompasses comprehensive strategies for removing contaminants, residues, and potential hazardous materials from specialized equipment, machinery, and workspace environments. Cleaning validation processes require meticulous documentation and risk assessment to establish consistently effective cleaning methodologies that meet predefined cleanliness standards.

The scope of industrial cleaning varies dramatically across sectors, with each industry developing unique protocols tailored to specific environmental challenges. For instance, tank cleaning in chemical and food production involves specialized techniques like hot and cold water washing, chemical treatments, and careful management of biological contamination. These processes demand precise technical knowledge, advanced equipment, and strict adherence to environmental and safety regulations.

Pro tip: When evaluating industrial cleaning services, request comprehensive documentation demonstrating their validation processes and compliance with industry-specific regulatory standards.

Common Types of Industrial Cleaning Services

Industrial cleaning services encompass a wide range of specialized techniques designed to address unique environmental challenges across different sectors. Commercial cleaning services represent a comprehensive approach that includes daily maintenance, deep cleaning, and targeted sanitization strategies for various professional settings.

Key types of industrial cleaning services include precision equipment decontamination, which involves intricate cleaning protocols for sensitive machinery in pharmaceutical, electronics, and manufacturing environments. Specialized services like tank cleaning for chemical and food production facilities require advanced techniques involving hot water, chemical treatments, and strict environmental management protocols. Other critical services include high-pressure washing, industrial floor cleaning, hazardous material removal, and comprehensive sanitization for critical infrastructure.

Post-pandemic developments have significantly expanded the scope of industrial cleaning services, with increased emphasis on comprehensive disinfection and biosecurity measures. These services now integrate advanced technologies like electrostatic spraying, UV-C sterilization, and ATP testing to ensure thorough contamination prevention. Different industries demand unique approaches, from sterile pharmaceutical environments requiring microscopic particle removal to heavy industrial settings needing robust mechanical cleaning techniques.

Pro tip: Request detailed documentation of cleaning validation processes and industry-specific certifications when selecting an industrial cleaning service to ensure comprehensive and compliant sanitization.

Essential Methods and Cleaning Technologies

Industrial cleaning technologies have evolved dramatically, offering increasingly sophisticated methods for removing contaminants and maintaining precision environments. Aqueous cleaning techniques represent a critical advancement, utilizing water-based solutions with specialized detergents and surfactants to effectively clean complex surfaces while minimizing environmental impact.

Advanced cleaning methodologies span multiple approaches, including chemical, mechanical, and physical decontamination strategies. Ultrasonic cleaning technologies use high-frequency sound waves to dislodge microscopic particles from intricate equipment surfaces, while high-pressure water jet systems provide powerful mechanical cleaning for robust industrial environments. Specialized cleaning protocols are particularly critical in sensitive sectors like semiconductor manufacturing, pharmaceutical production, and aerospace engineering, where contamination can compromise entire production processes.

Modern industrial cleaning technologies integrate sophisticated diagnostic and verification systems to ensure comprehensive sanitization. These include ATP testing for biological contamination, spectroscopic analysis for surface residue detection, and advanced imaging technologies that can identify microscopic impurities invisible to the naked eye. Cutting-edge approaches like plasma cleaning, electrostatic disinfection, and laser-assisted decontamination are pushing the boundaries of what’s possible in industrial sanitization, offering unprecedented levels of precision and effectiveness.

Here’s a summary of key industrial cleaning methods and their typical industry applications:

| Cleaning Method | Main Advantage | Typical Application |

|---|---|---|

| Ultrasonic Cleaning | Removes microscopic particles | Pharmaceuticals, electronics |

| High-Pressure Washing | Handles heavy grime and residues | Manufacturing, food processing |

| Aqueous Cleaning | Environmentally friendly | Aerospace, precision engineering |

| Chemical Treatments | Removes stubborn contaminants | Chemical, medical device sectors |

| UV-C Sterilization | Eliminates biological hazards | Healthcare, biotech facilities |

Pro tip: Always request comprehensive cleaning validation documentation that demonstrates specific testing methodologies and contamination detection protocols used during the cleaning process.

Compliance Requirements and Safety Standards

Industrial cleaning operations must navigate a complex landscape of regulatory requirements designed to protect worker safety and environmental integrity. Industrial hygiene standards establish critical guidelines for recognizing, controlling, and mitigating workplace hazards associated with cleaning processes, encompassing chemical handling, protective equipment, and risk management protocols.

Comprehensive safety standards address multiple dimensions of industrial cleaning risk management, including chemical exposure, biological contamination, ergonomic considerations, and personal protective equipment requirements. Different industries maintain unique compliance frameworks, with pharmaceutical, medical, and food processing sectors typically enforcing the most stringent protocols. Key regulatory bodies like OSHA, EPA, and industry-specific commissions mandate detailed documentation, employee training, equipment certification, and regular safety audits to ensure comprehensive workplace protection.

Modern compliance strategies integrate advanced technological solutions for monitoring and verifying safety standards. These include real-time exposure tracking systems, automated chemical management platforms, comprehensive training management software, and sophisticated personal protective equipment that provides enhanced monitoring and protection. Organizations must develop robust internal protocols that not only meet minimum regulatory requirements but proactively anticipate potential safety risks and implement preventative measures.

Pro tip: Develop a comprehensive safety compliance checklist that includes regular equipment inspections, updated training documentation, and detailed incident reporting protocols.

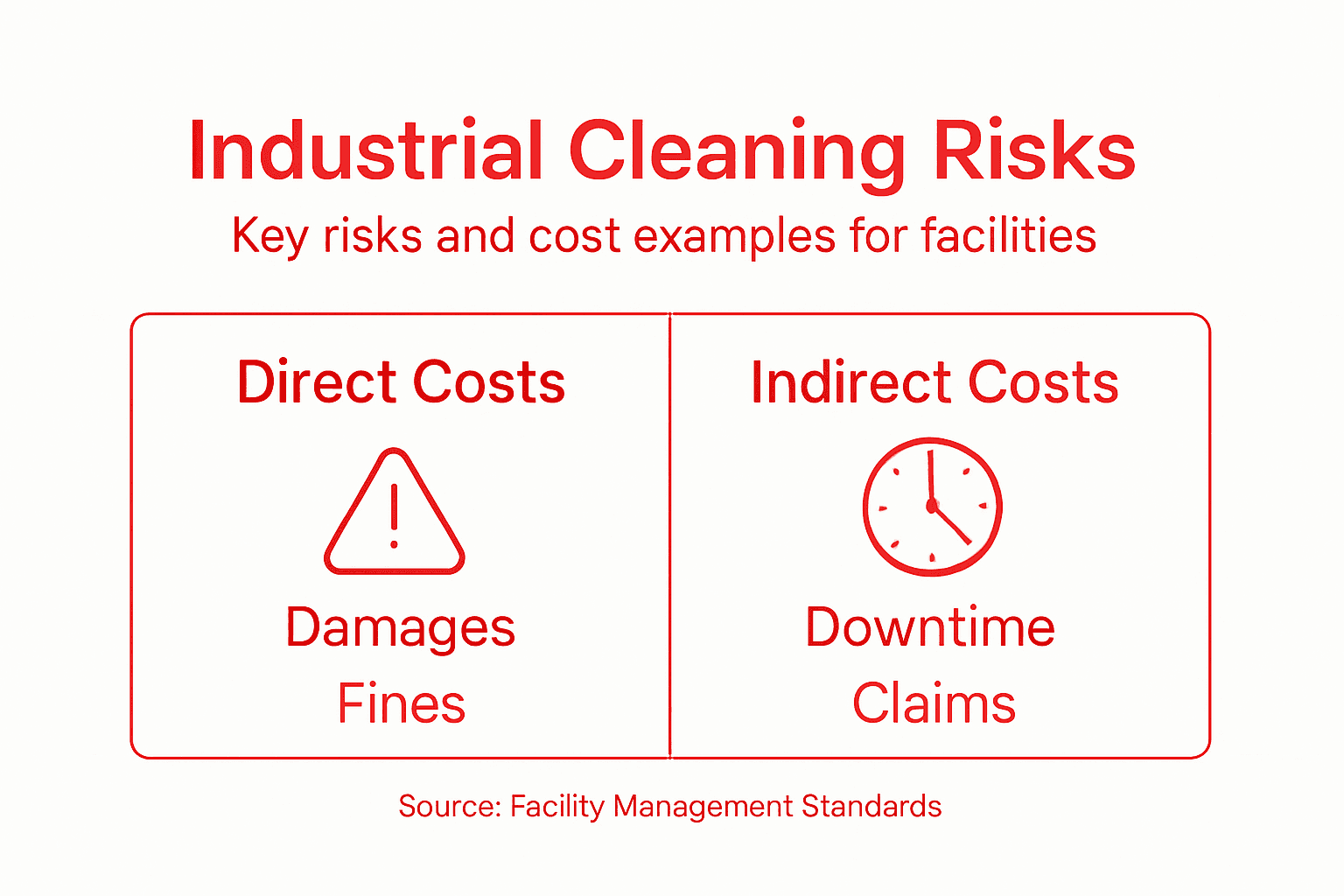

Risks, Liabilities, and Cost Implications

Industrial cleaning processes present complex financial and legal risks that extend far beyond immediate operational expenses. Cross-contamination risks can create substantial liability exposure, particularly in sensitive industries like pharmaceuticals, food processing, and medical manufacturing, where contamination incidents can trigger catastrophic financial and reputational consequences.

The potential financial implications of inadequate cleaning protocols are profound and multifaceted. Direct costs include potential product recalls, equipment replacement, regulatory fines, and legal settlements. Indirect costs encompass reputation damage, lost production time, increased insurance premiums, and potential long-term business relationship disruptions. Industries with stringent quality control requirements, such as pharmaceutical and medical device manufacturing, face exponentially higher stakes, where a single contamination event can result in millions of dollars in potential damages.

Compare the primary costs and risks associated with industrial cleaning lapses:

| Risk Type | Direct Cost Example | Indirect Consequence |

|---|---|---|

| Cross-Contamination | Product recall expenses | Loss of client trust |

| Regulatory Breach | Fines and penalties | Increased insurance premiums |

| Equipment Damage | Repair or replacement | Production downtime |

| Inadequate Training | Injury settlements | Reduced workforce morale |

Risk mitigation strategies must incorporate comprehensive documentation, rigorous validation processes, and proactive monitoring systems. This requires significant upfront investment in advanced cleaning technologies, employee training, and sophisticated quality control mechanisms. Organizations must develop robust risk assessment frameworks that continuously evaluate cleaning methodologies, identifying potential vulnerabilities before they escalate into costly incidents. Advanced technologies like real-time contamination detection systems, predictive maintenance platforms, and comprehensive documentation software can help organizations minimize their risk exposure and demonstrate due diligence.

Pro tip: Implement a comprehensive risk assessment protocol that includes regular third-party audits, detailed documentation of cleaning procedures, and continuous staff training to minimize potential liability exposure.

Ensure Your Facility Meets the Highest Industrial Cleaning Standards

Industrial cleaning requires rigorous processes to eliminate contaminants and meet strict compliance standards. If your facility faces challenges with maintaining operational efficiency, managing risk, or adhering to safety regulations, you need a trusted partner with expert knowledge and proven techniques. At Nu-England Services, we understand the importance of thorough cleaning validation, precise sanitization methods, and environmental responsibility to protect your assets and workforce.

Discover how our Commercial Cleaning – Nu-England Services solutions incorporate advanced cleaning technologies and comprehensive safety protocols tailored for complex industrial environments. From contamination prevention to equipment care, our experienced team delivers reliable services backed by decades of local expertise.

Take control of your facility’s cleanliness and compliance today. Visit Nu-England Services to request a free quote and explore our full range of Cleaning Services – Nu-England Services. Secure your operations now with professional support that prioritizes quality, safety, and sustainability.

Frequently Asked Questions

What is industrial cleaning?

Industrial cleaning refers to a specialized approach to sanitizing and maintaining complex facility environments, involving rigorous processes designed to meet strict regulatory standards and ensure operational efficiency.

What types of services are included in industrial cleaning?

Industrial cleaning services include precision equipment decontamination, tank cleaning, high-pressure washing, hazardous material removal, and comprehensive sanitization, tailored to the unique challenges of various industries.

What technologies are used in industrial cleaning?

Modern industrial cleaning technologies include aqueous cleaning techniques, ultrasonic cleaning, high-pressure water systems, chemical treatments, and UV-C sterilization, aimed at effectively removing contaminants and ensuring precision in sensitive environments.

What compliance requirements must industrial cleaning operations meet?

Industrial cleaning operations must adhere to various regulatory requirements that ensure worker safety and environmental integrity, including safety protocols, documentation, employee training, and regular safety audits dictated by regulatory bodies.